Multi Pallet Handlers for Forklifts

Efficient pallet transit starts with the proper hydraulic fork positioning. The attachment type determines the number of pallets transported. Robust frame construction offers durability and safety with each operation. Constant lateral adjustment is implicit.

-

Double Fork Positioner LM1 (1-2 Pallets)

The LM1 hydraulic attachment is a time-saving pallet handling solution. It is designed to carry 1-2 pallets and ensures quick and precise operations. Its compact design maximizes the operator’s field of vision. The durable construction, automatic greasing system, and sturdy load support make it ideal for heavy-duty use. The LM1 model can handle one or two pallets with a fast transfer rate. This makes it an indispensable handling machine for palletized materials.

- Automatic greasing system option

- Solid load carrier

- Quick change through screw connections

- Chrome-plated guides for longer bearing life

- Balanced forks through high-quality hydraulics

- Encapsulated bearings on standard inner forks

Additional Information:

- Two hydraulic functions required

- Includes hoses and couplings

- Constant side shift as standard

- No side shift reduces price (ISO II, III, IV)

- Optional great field of vision load backrest (ISO II, III)

- Automatic oiling system on request

- Scanner holder on request

-

Double Fork Positioner LM2 (2-4 Pallets)

The LM2 forklift lifting equipment model is able to handle 2-4 pallets without effort. Its hydraulic fork positioning and extra fork length allow for multiple handling, reducing distances between pallets. The sturdy frame ensures longevity, while the compact design maximizes visibility. Standard side spacing alteration and optional features increase adaptability in various handling processes.

Additional Details:

- Requires two hydraulic functions

- Includes hoses and couplings

- Standardizes constant side shift

- Cost reduction for no side shift (ISO II, III, IV)

- Opt for high visibility load backrest (ISO II, III) if desired

- Request automatic oiling system for side shift top

- Scanner holder available upon request

-

Triple Fork Positioner LM3 (1-2-3 Pallets)

The LM3 lifting attachment is a go-to for handling 1-2-3 pallets. Due to its hydraulic fork positioning, lifting and transporting are seamless. Its robust frame ensures duration and safety. Standard side shift adds flexibility. This fork positioner model enhances adaptability, making it versatile for various needs. Adapt to diverse operational demands seamlessly with this advanced tool, ensuring every lift and transport is a smooth and reliable experience. The LM3 stands as a dependable solution for enhancing material handling capabilities.

Additional Information:

- Optimum operation: requires two hydraulic systems, hoses and couplings

- Standard function: constant displacement for operational adaptability

- Cost-saving option: omit lateral movement (ISO II, III, IV)

- Visibility adaptation: request optional high visibility backrest (ISO II, III)

- Improve operation: optional automatic greasing system available

- Scanner holder accessible on request

-

Multi Fork Positioner LM4 – Load-Extender (1-2, 1-2-3 Pallets)

The LM4 Multi Fork Positioner stands out for its ability to handle from 1 to 3 pallets with the help of its Load-Extender. This innovative attachment allows the loading and unloading of trailers through one side. Due to this, the workflow is optimized, and the productivity is boosted. This multi-fork positioner offers lateral movement. Its slim forks ensure versatility in pallet handling. The robust construction provides extended service life. This helps save costs and makes it an asset in any demanding environment. The extension stroke of the loading device adapts to the standard 2400 mm vehicle width. This ensures compatibility in various configurations.

To further enhance the user experience, customization options with a magnetic valve and automatic greasing system turn the LM4 into an accessory that meets unique operational needs.

Additional Information:

- Optimal function: requires three hydraulics, hoses, and couplings

- Standard feature: constant side shift ensures flexibility during operations

- Customization possibility: solenoid valve upon request (12V, 24V, 48V, 80V – available options)

- Enhance operations: request automatic greasing system for seamless functioning

- Visibility matters: consider optional high visibility load backrest (ISO II, III)

-

Multiple Fork Positioner LM5 (2-3-4, 6-8 Pallets)

The LM5 multi-fork clamp attachment can efficiently handle 2-3-4 or as many as 6-8 pallets.

Engineered precision: hydraulic fork positioning ensures smooth and controlled pallet handling. The stable frame construction provides sturdy support for the forks. It further facilitates a high turnover of goods. Flexibility is ensured with standard side-shift functionality in material handling processes. Production increases with options such as an automatic oiling system. The LM5 is a versatile and efficient forklift accessory that adapts to different pallet handling needs.

Additional Details:

- Optimal function: requires two hydraulics, hoses, and couplings

- Inclusive: includes standard constant side shift for operational flexibility

- Custom options: request an automatic greasing system for seamless functioning

-

Fork Positioner with Weighing Forks

Material handling is streamlined with the Fork Positioner’s innovative weighing forks. Constant lateral movement ensures greater control and precision in pallet handling. The stable, shaft-guided, welded frame guarantees reliability in its construction. Bolt-on forks ensure practicality and ease of use for efficient handling practices. Enhance material handling experiences with the help of this fork attachment, ensuring precision and safety in every operation.

A Li-ion battery pack (12/24V) powers the fork positioner accessory. This way, it guarantees resistance and eco-friendliness. Designed for smaller carriages, it can accommodate longer forks. Another advantage of this product is that it boosts versatility in material handling operations. Encounter increased performance without compromising precision using this forklift tool. It adapts to various material handling requirements. In consequence, it merges accuracy and environmental consciousness. The final result is an optimized operational experience.

Additional Information:

- Optimal function: requires two hydraulics, hoses, and couplings

- Comprehensive: includes standard constant side shift for operational flexibility

- Standard feature: includes bolt-on forks for practicality

- Modern power supply: utilizes a Li-ion battery pack

- Versatile design: suitable for longer forks in material handling

- Restriction: clamping of goods is not allowed for safety measures

-

Accessories

Logimarkt offers innovative accessories for the forklift attachments. These enhance visibility, ensure safer operations and increase efficiency. The product range offer clear views, optimize workflow and reduce risks.

Benefits:

- Enhanced Visibility: Improved sightlines during load handling

- Enhanced Safety: Reduces risks for personnel and cargo

- Damage Prevention: Minimizes potential damages to goods and packaging

- Cost Efficiency: Saves expenses by reducing damages

- Ergonomic Upgrade: Promotes ergonomic posture, reducing strain

- Time Savings: Facilitates quicker and safer navigation

- Simplified Loading: Integrated sensors streamline loading processes

Product Line:

Laser Secure

- Safely loads goods

- Detects pallet ends effortlessly

Frontal Camera

- Expands visual range

- Targets load carriers precisely

- Detects obstacles during loading

- Suitable for various types of trucks

- Equipped with lighting for clarity

LED Flash

- Provides visibility in dark environments

- Decreases accident rates

- Customizable LED display

- Useful for depth determination

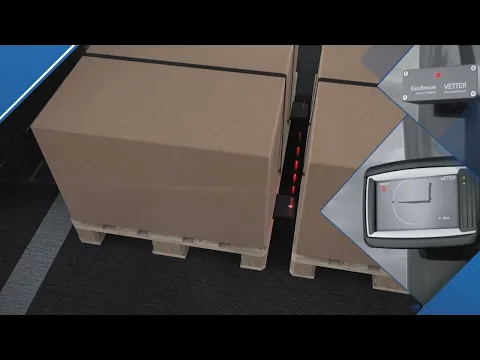

Laser Secure for Stacked Pallets

- Ensures safe transport

- Accurately detects distances

- Facilitates precise fork pocket entry

- Minimizes damage to transported goods

- Provides clear view ahead of the load

-

Fork Positioners are carefully designed to boost material handling efficiency. LM1 for 1-2 pallets, LM2 for 2-4, and LM3 for 1-2-3 are versatile, optimized, and adaptable solutions. Each product is engineered with precision and durability as a top priority.

The LM4, equipped with Load-Extender, facilitates one-sided loading for 1-2 and 1-2-3 pallets. Yet, the LM5 Multiple Fork Positioner handles 2-3-4 and 6-8 pallet configurations.

If precision weighing and constant side shift capability are crucial, the Fork Positioner with Weighing Forks ensures unparalleled control. Elevate material handling processes with these advanced solutions, catering to diverse operational needs.

Industries that can benefit from using the Forklift Attachments:

- Warehousing: Optimize pallet handling and enhance efficiency.

- Manufacturing: Use the fork positioner tools for varied pallet sizes to improve material flow.

- Logistics: Streamline operations by equipping forklifts with clamp attachments for versatile pallet manipulation.

- Retail Distribution: Boost supply chains by accommodating diverse pallet configurations.

- Construction: Increase site productivity by adapting forklifts with lifting positioners for flexible material handling.

- Automotive: Improve material handling in the automotive industry using fork positioners for precise pallet control.

- Food Industry: Efficient material handling with forklift attachment for diverse pallet sizes.

- Paper Industry: Enhance paper fabrication by including hydraulic fork positioners for optimized pallet handling.

- Pharma: Increase precision in pharmaceutical material handling by improving overall workflow.

- Recycling: Boost recycling centre operations using forklift extensions to handle varied materials safely.

Innovation is chosen. Efficiency is chosen. The fork positioners from Logimarkt Engineering are chosen for an innovative approach to material handling.