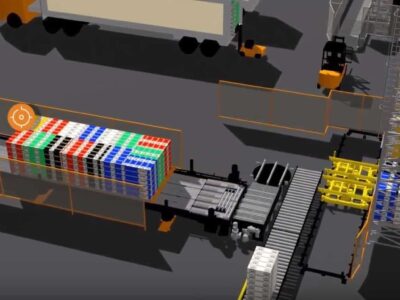

Automated truck loading system

For classic transport methods (sea containers, trucks), this automated system represents a fast and tested loading way in one single move.

It is compatible with palletized or oversized loads, goods which need special loading conditions and the container doesn’t allow this, profiles and pipes or timber, goods which cannot be containerized or are easy to deteriorate, etc.

The automated truck loading system implies first the placing of the load on the standard platform. This one is very thin, so the total height of the load doesn’t have to be decreased. The load is then pushed inside the container (tow). When the load in completely in, a stopper gets down and blocks it inside while the platform is retracted from underneath it. In the end, the load is the only one which stays inside the container.

The initial platform can be loaded:

- traditionally, with forklifts

- with cranes in case of long tubular products like pipes or wood/timber and the loading is done on top

- with conveyor or shuttle systems

The system configuration may vary, from fix platforms to mobile ones which are movable depending on the loading point, from the manually controlled models to the PLC control ones.

The benefits of the automated loading systems for trucks are:

- better loading time by shortening it to less than 5 minute

- time save by preparing in advance more platforms with goods which are then aligned on the loading zone

- the load can be supplementary loaded also on the long laterals (lengths) or on top

- there are cost decreases by loading standard containers instead of roofless containers with top loading

- the system can be used indoors and outdoors

- it can be loaded by a single operator, without any other supplementary equipment

- there is a decrease of the number of forklifts needed for loading, these being relocated if necessary, in other activity areas

- during the loading process there is no need for any operators inside the truck, this meaning 100% safety for the human resource and maximum efficiency by less physical work

- the expenses are decreasing due to elimination of damages caused by the classic loading system

- important ecologic component by lower CO2 emissions